A brief rehashing of things I learned from making electronic devices for a living (or so I tell myself). More stuff you already know after the jump.

Know yourself:

We engineers are all heroes capable of amazing feats but be realistic and conservative when estimating delivery dates. Doing things in a rush never is good and almost always will result in some sort of sloppy work.

Pulling an all nighter is okay from time to time, more even so if you are inclined to the software side but remember to have proper rest. This is an extreme case but I think it serves well as an example: Yale Student Killed in Lathe Accident [MAKE]. My “zone” is normally from 17-24 and I’ll happily extend it if I could avoid waking up early; the point is: plan your schedule so you can work on your most productive time and also have adequate resting.

Invest in tools:

If you are in a hurry or short of money buy whatever you can, but quality tools will make your life a lot nicer. There are many variations of the same tool, and they can be a very good time saver so while you are shopping look a bit for alternatives instead of buying just what you need that moment. My new favorites are angled nose pliers; with them I can work comfortably in a board without having to put them aside when it’s time to switch to another board. That alone saves me about forty minutes in a normal production run.

While we are at this buy an ergonomic chair with lumbar support and good lighting as soon as you can. It doesn’t have to be an Aeron but trust me that you will not regret buying it in a couple of years.

Also using both hands is a good skill to acquire; we southpaws have this more or less in our lifestyle but it also helps to relieve/avoid RSI injuries.

Work in batches:

This will improve your usage of time. After a while every repetitive action becomes kind of natural. For the above board I had to bend pins on 240 resistors; if I bent one, then placed it on the board, picking another… and so on I’d still be on that. After the first board I could bend them without even looking. (As soon as I can I’ll build a machine to automagically bend the tapes).

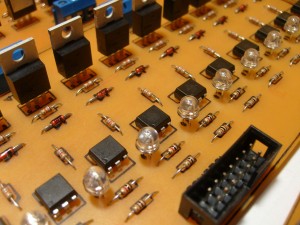

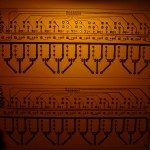

In this particular case I mounted first every resistor, then diodes, then optocouplers, terminals and lastly the fets.

Be tidy and pay attention to every possible detail:

This goes both for your bench and your work. I like to have four clear areas in my bench: tools for the current task, required components, boards to be processed and finished boards; it’s almost like a fordist line. Everything else is either on another table or stored in shelves. This is a not so very good shot of my in-house workbench:

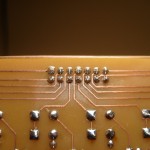

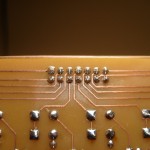

You could be a genius but at the end you’ll be seen through your work, so make things neat and tidy as possible. Many oversee little details like orienting all the resistor the same, leveling components and attaining a good finish on the solder side (clean up the flux!). Don’t do a sloppy job, it could be the difference between establishing a solid relationship and never working again with that person.

Leave your ego aside:

We like to see our name in things and so does our customer. Refrain from putting your name/logo unless being told so, just use the brand of your customer.

Keep your customer informed and be honest:

Even if it’s a one week work give frequent progress reports, send some pictures if you can. It is not nice to work with someone who “disappears” and then magically comes with something.

Sometimes I have to mail-order components because the local shops don’t have them or don’t have enough stock. In that case I give a tracking number to the customer so she/he can know what’s happening and when I’ll start working. (if possible do some other part of the job so you don’t waste time).

In the (hopefully rare) event that something goes awry tell as soon as you can, be sorry if appropriate and offer means of resolution.

Don’t work for free:

It might be tempting to work for very cheap rates when you start but don’t lower the bar that much, it will bite you later. It’s okay to have low prices but factor in not only the cost of raw materials but the time you take to make it and every ancillary task required. Being cheap involves the risk of a sudden peak of demand with no time nor resources to satisfy it (you don’t happen to have a complete and automated production line on your basement, don’t you?).

If you cannot build another unit for free with your profit margin and still have earnings(say, because your pet destroyed one) in 99% of cases you are doing it really wrong.

Have a backup:

Don’t depend on a single supplier, keep in mind mail delays when working with foreign customers (it is very frustrating to miss a deadline because the transport company had some issues) and buy excess of components if you cannot stock them easily. When making long runs the odds of having failing components have more weight and paying 30$ in postage for a 9$ transistor hurts (and takes time). Also, watch out for duds. This diode felt weird (I mostly place them sensing the bevel and the shorter pin), the casing is reversed:

Test!:

This should go without saying but I’ve seen people deliver boards blindly believing that they work. Just don’t.

Design for ease of manufacture and service:

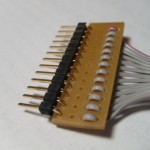

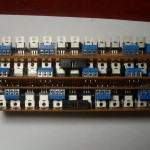

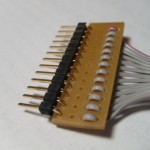

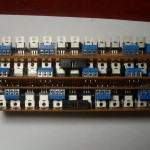

It is not easy to give general guidelines but keep in mind that you are going to assemble whatever you design, so think a while before diving into making stuff. If possible use only stock parts (see below for a home made connector I had to make. Avoid situations like that). If you can go full or mostly surface mount do it, the time saved from drilling and then mounting components is worth every bit of hassle required to learn how to do smd work. Lastly, think about things like ease of mounting, use and stacking. I like to use proportions based on 2, 4 or 3 to distribute elements but sometimes it is not the best option, despite looking good, as the last picture shows.

Sell yourself:

Word of mouth is a very good way to reach more people but sometimes not enough. There are many places where you can advertise your services (even free ones). It really helps to have some sort of showcase or portfolio available. It’s a plus if people can put your name in a search engine and land directly into it (also remember that the net does not forget).

Further reading:

Two influential articles:

Steve Friedl: So you want to be a consultant…?

James Chan: Spare Room Tycoon (Buy it if you can)

Corollary:

Whatever you end up doing, be happy.

- Looks nice, eh?

- The components just arrived from the mail. That’s like $500 worth of mosfets.

- It could be tidier.

- Clean up that flux!

- This is much better.

- IDC connectors, the best thing since sliced tuna.

- Last resort connector. Avoid this kind of things at all costs.

- Led with anode and cathode swapped.

- Sometimes the center is not really the best place.