Long time ago I was waiting for my turn to use the weighting scale on a scrapyard when I stepped over something curious.

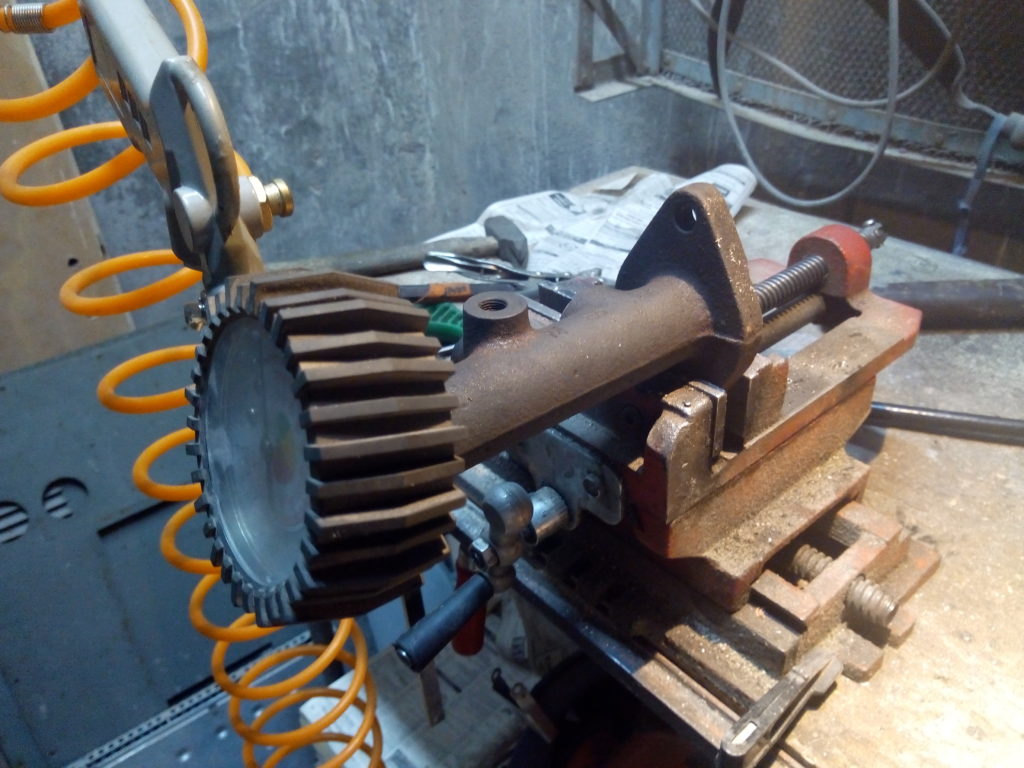

Inside a sturdy chunk of mud there were the remains of an electric drill but what got my attention was the keyless chuck. I asked at the counter and got it for free.

It slept for some time on a shelf until I found it again cleaning. It resisted a civilized dismantling intent so I bathed it overnight in a mix of gasoline and paint thinner.

The front came out easily and looked good enough given it’s history except for a couple of spots with tool wounds and corrosion with significant missing iron. Seems it had been passivated on the inside.

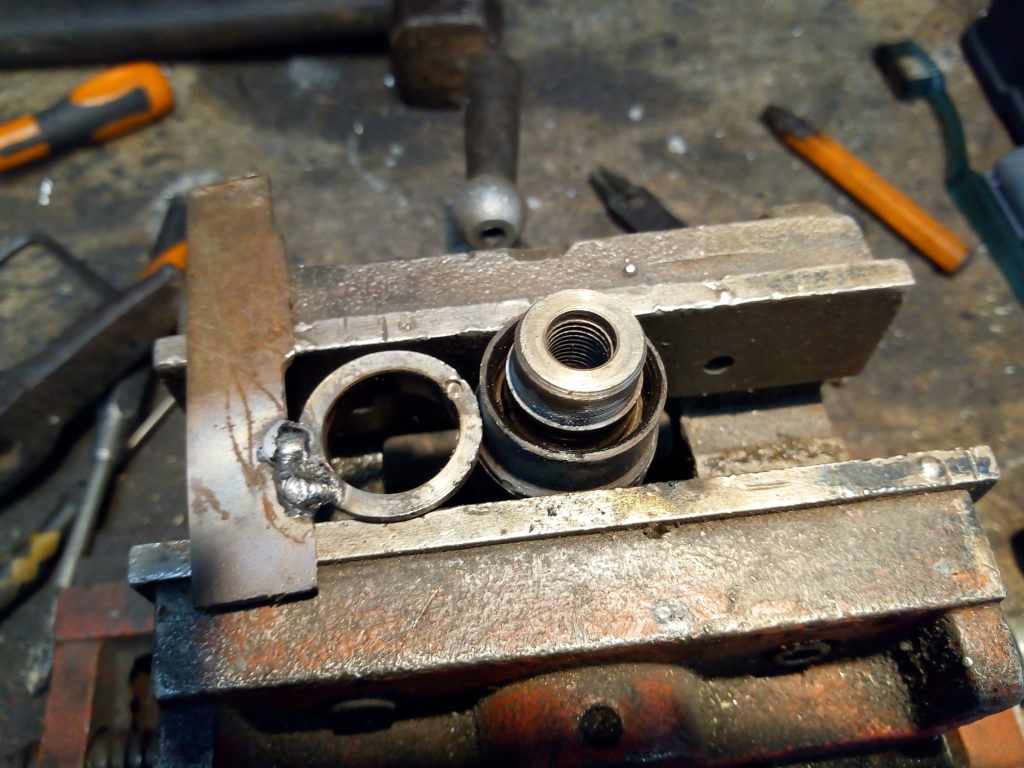

There’s a two hole pig nut on the back and that one gave more trouble. I first tried with a round nose pliers and then a punch but it only made things worse.

I used a heat gun to clear any remnant of gasoline, hoping that it would loose the threads but no cigar. So I welded a piece of scrap and with that I managed to pry it.

Compared to the rest this part looked much better. I expected a ball bearing but there was only a hardened steel ring instead.

I padded a couple of beads on the body and after a bit of careful grinding it’s like it never spent time buried.

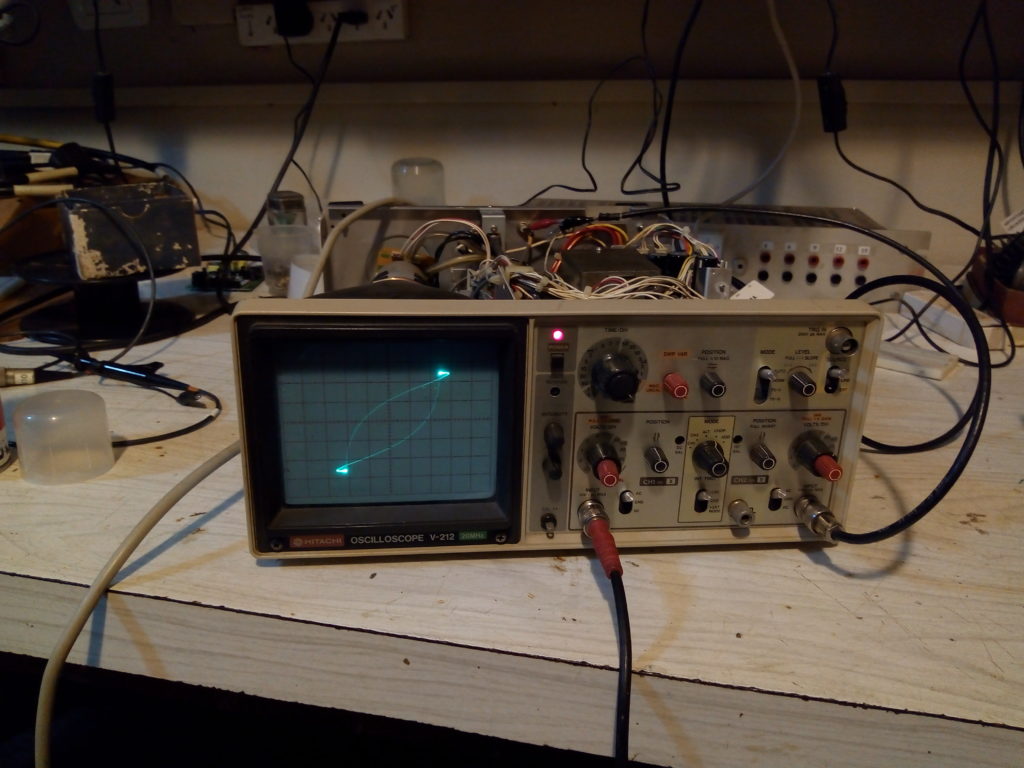

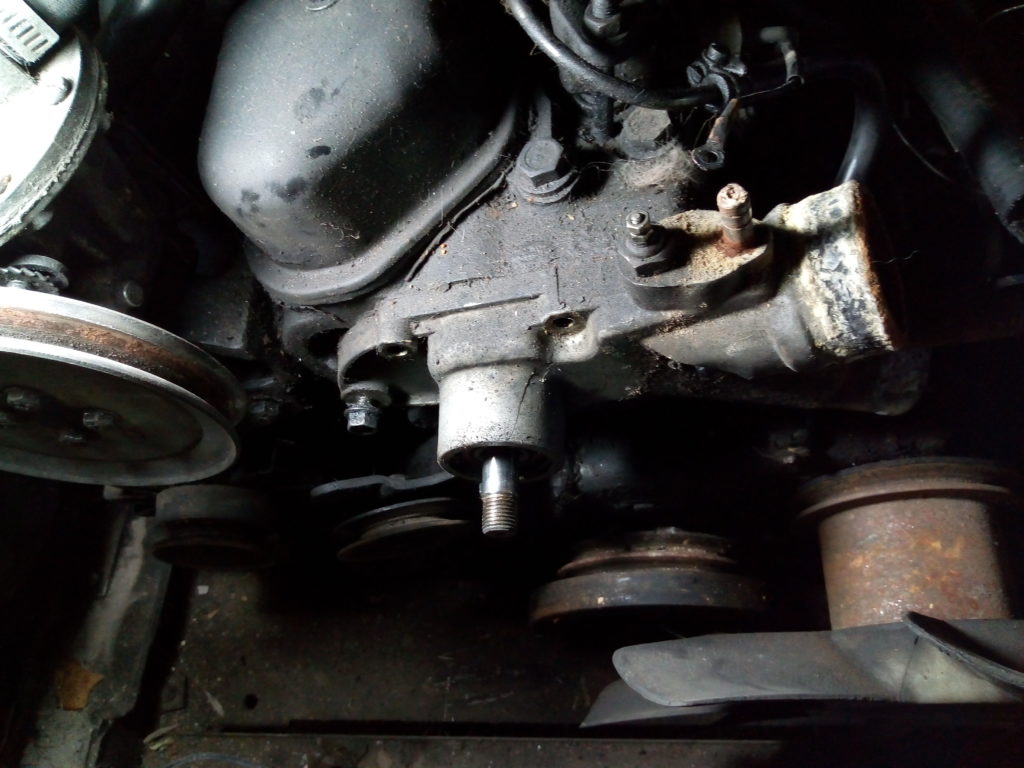

Now I only have to fix the horrible amount of run-out and play of the drill press.

Albrecht chuck repair: taking it apart

Albrecht chuck repair: taking it apart

Albrecht chuck repair: everything in pieces

Albrecht chuck repair: jaws

Albrecht chuck repair: jaws

Albrecht chuck repair: patched up body

Albrecht chuck repair: back into service