Some days all I want to do is smash a hard drive to pieces and pour them into a roaring fire.

Some days all I want to do is smash a hard drive to pieces and pour them into a roaring fire.

Today after waiting more than a year since I built them, I finally installed the rollers on our lamp fixture. I also exchanged the roof mounts with something sturdier. Now I only have to retouch the paint on a couple of spots and perhaps build a better winch to pull on all the ropes.

Well turns out that puller works with a bit of effort to keep it from buckling. So I used it to finish a belt sander that has been waiting on the bench.

Because this bearing made an unbearable amount of noise:

It’s amazing how much damage heat and wood dust can do. This was a 608-2RS and the metallic plates behind the seals were worn just paper thin.

Today was one of those days when in order to do something I say to myself “I need this tool and (especially now) I can not buy nor justify buying it. So let’s build one”.

And that in itself takes more time than the whole project.

I was in the process of fixing an old dentists lamp that was laying around, the fresnel lens was originally held with some tiny and feeble metal strips that were in horrible shape.

Instead of making a replacement with some leftover stock or filler rods I decided to make a proper retention ring with sheet metal from a computer case.

But, my simple compass wasn’t able to make circles as big as I needed. Thus I set to build a beam compass.

I had the hardened points from a couple of broken punches, so it was only a matter of cross drilling some bolts and figuring out how to end up with something that would be useful.

Except from the bolts everything else came from either the rust bucket or the trash.

There are a lot of things that can be improved but as it is, it fulfills its intended purpose just fine:

Pity that it’s already too late to start the plasma cutter and finish this part.

Part of the frame for a small overhang roof.

I used clear standard automotive hoses for the steam boiler in order to have at a quick glance the water level. They are “rated” at 4 bar but having hot stuff inside certainly didn’t help and with a small hissing warning they sprung a leak that turned into a nice jet of steam.

The pressure is low but in any case standing nearby when that happened was a bit startling.

I’ve been wanting for quite a while to indulge in my steam interests and last week was the perfect moment to give them a spin.

A couple of blocks from here there’s a facility that bottles carbonated water but also rents hot/cold dispensers. From time to time they swap the boilers when the limescale fouls them; discarding the whole unit, thermostat, heater and all.

Every time I walk past their door I pick one or two if they are not pitted. They are very nice, made of stainless and have a lot of uses.

Continue readingLong time ago I was waiting for my turn to use the weighting scale on a scrapyard when I stepped over something curious.

Inside a sturdy chunk of mud there were the remains of an electric drill but what got my attention was the keyless chuck. I asked at the counter and got it for free.

It slept for some time on a shelf until I found it again cleaning. It resisted a civilized dismantling intent so I bathed it overnight in a mix of gasoline and paint thinner.

The front came out easily and looked good enough given it’s history except for a couple of spots with tool wounds and corrosion with significant missing iron. Seems it had been passivated on the inside.

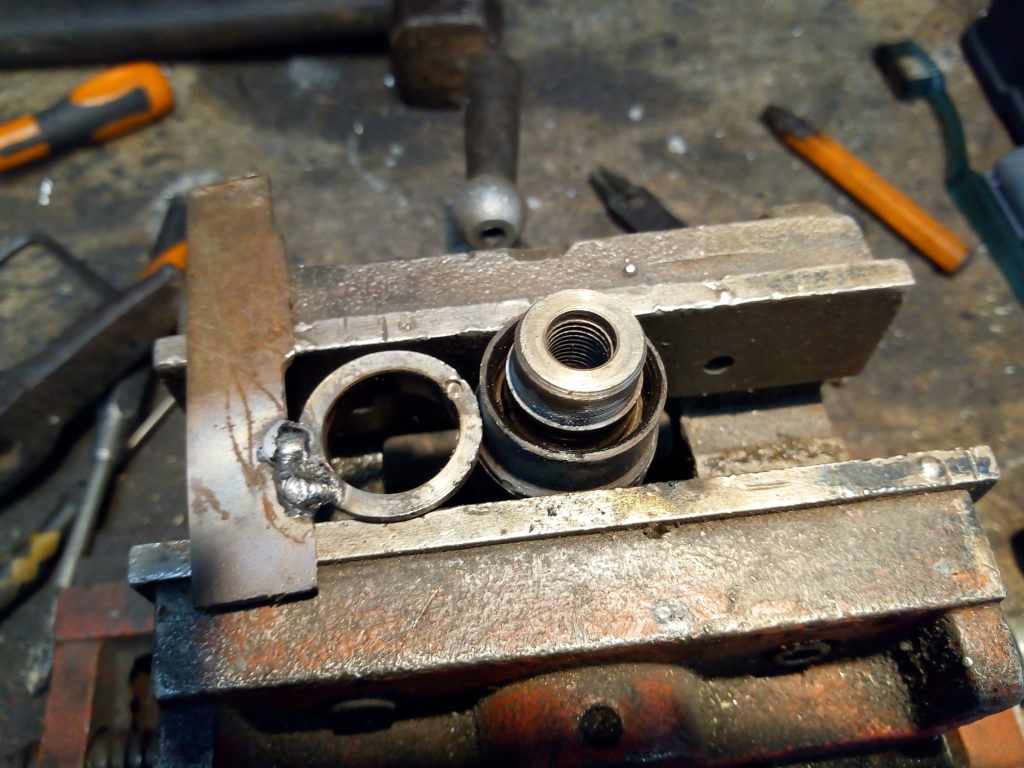

There’s a two hole pig nut on the back and that one gave more trouble. I first tried with a round nose pliers and then a punch but it only made things worse.

I used a heat gun to clear any remnant of gasoline, hoping that it would loose the threads but no cigar. So I welded a piece of scrap and with that I managed to pry it.

Compared to the rest this part looked much better. I expected a ball bearing but there was only a hardened steel ring instead.

I padded a couple of beads on the body and after a bit of careful grinding it’s like it never spent time buried.

Now I only have to fix the horrible amount of run-out and play of the drill press.

Long ago I won a lot of used tools at an auction. Among them there was a small two ton jack.

Overall it was in fair condition but the lever was really hard to move, so I left it with other low priority things to repair.

Upon a closer look the smaller piston was bent. I chucked it into a vise and tried to loose the nuts but they were firmly stuck.

I cleaned the base with a rag and wire brush and then welded it to a piece of iron channel. I love 6010 rods. I also learned that whatever was used as hydraulic oil catches fire with ease.

Laying on the floor with one foot on it I used a big wrench and a hammer, this time succeeding in getting it apart.

It doesn’t seem like much but this small curvature made it almost impossible to pump:

I decided against straightening because with the tools I have at hand it would be very certain that I’ll scratch the good part of it and thus completely ruining the jack. So I cut the bent parts with an angle grinder.

Just by chance the parts that were badly out of shape are almost the same length as some ground rods I have from a textile machine.

The plan goes like this: drill and tap the remains of the original piston, make the rod hole bigger and use a long bolt to hold them in place.

I used the cutouts and some small welding rods from the trash to make a new cross handle.

I’m very proud of that weld, the ripples and profile are very smooth and consistent. But I had to grind it flush.

This is before the final assembly, now I can operate it with a single finger.

A while ago we were given a bunch of weathered wood from a deck. Some of us have been thinking of installing seats on the sidewalk and this looked like a good opportunity.

I looked around Core77 and there’s an entry just about seating that produced this helpful guide:

I built a simple frame with square tubing and used one of the wood packs to try it out. I need to select the best planks but it’s comfy and with a bit of paint will look good.

Every diamond starts as a lump of coal.

We needed a new stove for a long time and the other day I spotted this in an auction house for a fair price:

And with some care it ended up like this:

While preparing the existing floor for the new pouring I discovered remnants of the old building.

In its latest years (circa 1970-1980) it was used in a wine bottling operation as a storage room and later my grandad started to build a small studio for my uncle (but that project was cancelled due to things better not to speak of).

Before that, around the 30’s and 40’s, the whole house was a ceramic tile factory. Giant ovens to fire the clay, castings and all that.

As I started to dig the trench for the new waste plumbing I found what looked like the walls of a chamber or well of sorts. The top was made of reinforced concrete and had all the appearance of being a lid.

I tried to break and lift it with very little success. On the other extreme of the room there’s a hole that seemed to be a small opening made on purpose. I dug with my hand but only got sand, gravel and fragments of old tiles.

I gave up as whatever I removed from the floor had to get back and then some more to make a proper base layer for the next one. But I plan on digging further later on.

And a giant grinder.

Today I woke up early and instead of staying in bed reading until it’s a more convenient hour to start the normal daily activities I grabbed some fruit, a thermos and started to walk.

Just a block from home I spot a very old industrial grinder with a flexible coupling on the sidewalk. It’s quite heavy.

I continued to stroll around the city and saw the sunrise amid a gentle mist.

By the time I returned my brother was already awake and he lend me a hand to pick it up.

Surprisingly, it only took a couple of beats with a hammer and a wooden block to remove the coupling from the motor housing. The motor, a big and old three phase one, has all its wires crumpled and turns freely, albeit with a loud noise of broken bearing. On the other hand the shaft at the stone rides smooth, just like new.

If there’s a heaven I think I visited it today.

After running a couple of errands early in the morning I headed to Lisandro Olmos on the outside of the City to buy some scrap metal for my welding classes.

A couple of members of the group said good things about Grúas Mársico so I went there, it was also a good opportunity to travel a bit on this part, as I don’t know almost anything about it.

As I entered the warehouse I became speechless. There are shelves that extend up to the roof with parts from all kind of machines neatly organized on one side. On the other pieces of metal plate and tubing. Some big planers, milling machines and spot welders among them. And on the background, the tallest pile of industrial waste I ever seen in person. All of this on sale by weight save for a couple of weird stuff.

The shop was run by a very nice lady and her brother. This morning I only bought some iron but the next time I come around I’ll bring a small truck to pick some very , very interesting stuff.