Today after waiting more than a year since I built them, I finally installed the rollers on our lamp fixture. I also exchanged the roof mounts with something sturdier. Now I only have to retouch the paint on a couple of spots and perhaps build a better winch to pull on all the ropes.

Category Archives: futura

Retrieving passwords with tcpdump

The other night many weeks ago I chose to install Jitsi in one of our streamers.

I log into the OpenStack panel and make a quick resize of the instance.

Midway it barks and doesn’t come up. And nothing I can do from the console or there manages to un-stuck it from that state. So off it goes a ticket to support.

Meanwhile I spin another instance and rebuild the basic services.

In the heat of the night I forgot the set of users and passwords for the ingress streams. They were just there, in a volume attached to a zombie machine that I couldn’t access. And also in a backup disk just a room across, but I forgot about it back then.

Thankfully we got Nginx (and Traefik on the newer boxen) that take care of handling ssl, so inside everything is in the clear. All I had to do was

tcpdump -n -w dump 'tcp port 8000'and after a quick run with strings I had all the passwords again.

Christmas

The other day we had a Christmas dinner mostly like every previous years.

I’m not very much into receiving physical gifts but sometimes a little thing with a lot of thought can change everything. Long ago a couple of friends collaborated on an anthology of poems and the last weekend it arrived after a convoluted trip from Uruguay.

The result of their hard work is called “¡Dale Hermano! 20 Poetas del Río de La Plata”.

After the traditional toast I drove my grandma home and then went to say hi to a couple of friends.

The night was unusually quiet. After wandering without a clear intention for a while I parked at Parque San Martín and started to read.

The poems did not have the author with them but while reading I could imagine some of my friends reciting those and, upon looking at the index, I was most of the times correct in my guesses.

Thanks Mar and Pachi for such a great night.

Power off.

Today I replaced a couple of quick hacks with InfluxDB and Chronograf.

I like things that run without breaking:

# supervisorctl carbon RUNNING pid 1415, uptime 207 days, 19:49:57 graphite RUNNING pid 1419, uptime 207 days, 19:49:57 icecast RUNNING pid 24419, uptime 32 days, 1:11:18

Wiring progress

In the last couple of days I finished the remaining welds on the steel support and mounted it on the wall with some percussive persuasion.

Bad fitup

Steel reinforcement: installed

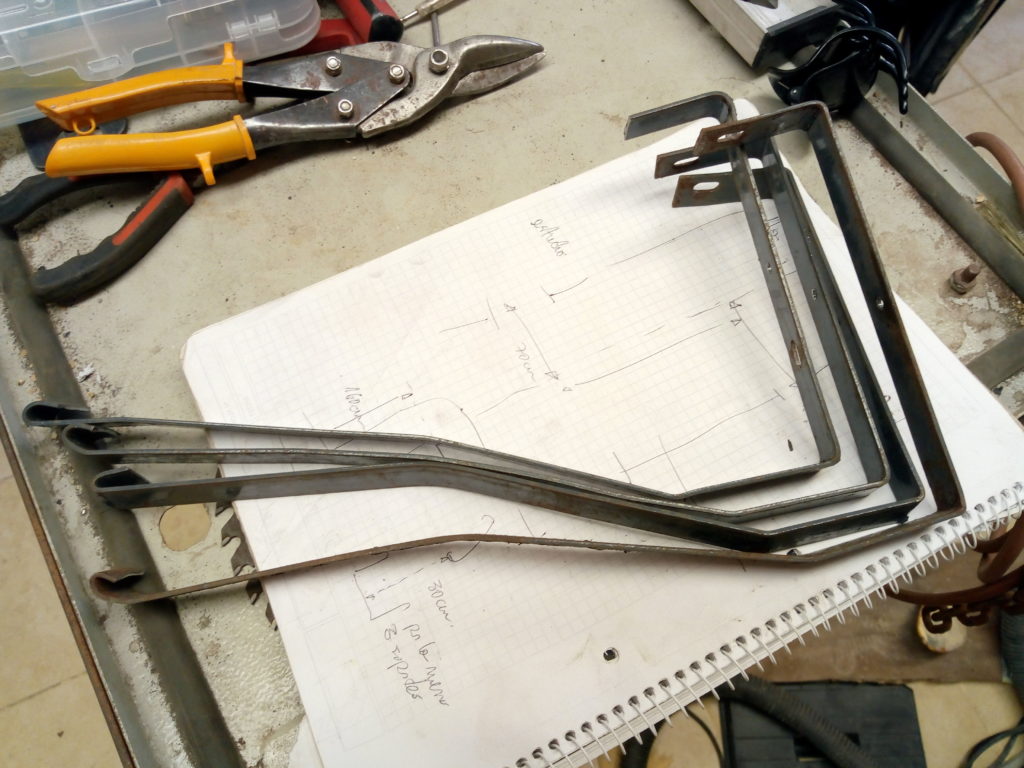

I made a couple of supports:

Cable tray hangers: levelling

Cable tray hangers

To hang this tray from the roof beams (I also made the mess of dust and bricks):

Cable tray snake

Weekend worklog

This weekend was a bit slow.

A couple of days ago I started to learn FreeCAD, mostly for its FEM analysis mode and to build a couple of construction plans.

I made another part of the cable trays for our comms closet. Initially I wanted to use FreeCAD for that but at the end it was faster to do a bit of trig and sketch the cuts on paper. It’s held in place with a couple of rivets. I also added a layer of pvc to shield the cables from the metal edges. Fits like a glove.

I also started to build a steel support for one of the walls. We made a big opening for cables and I’m a bit uneasy about the lack of support.

Fun with a plasma cutter follows:

Continue readingGlass door

These doors were waiting a long time to be installed. Now this looks a bit more professional than before, except that on the opposite side there’s a chunk of wall missing and a lot of dust on the new hole to feed another cable tray.

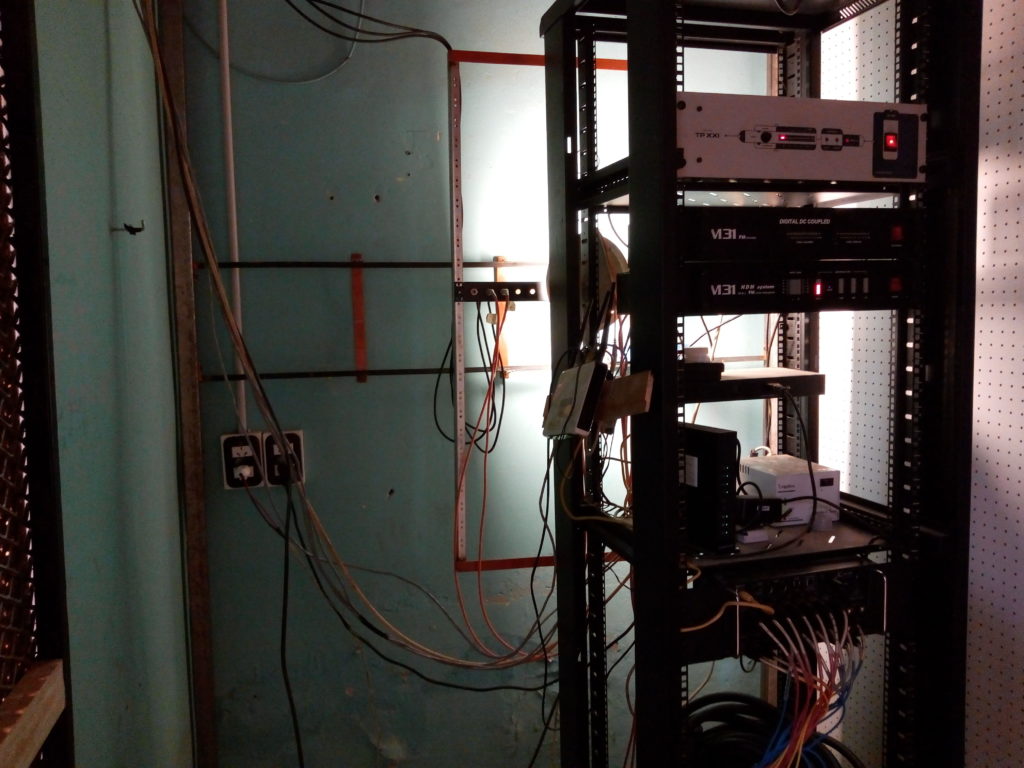

Comms and server rack at Futura

Comms and server rack at Futura

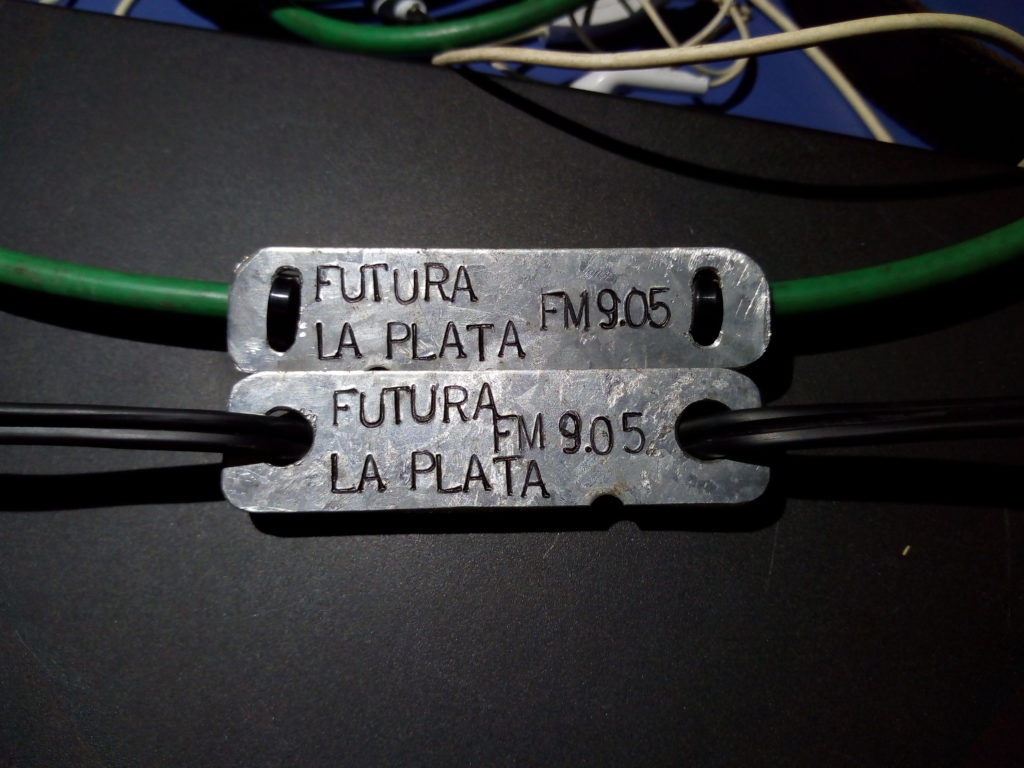

Name plate and tags

Well the remote control for our transmitter is officially finished. Today as a last detail I built a couple of name tags for the cables and a bigger plate to mount on the front panel.

They are not only for aesthetic purposes but also to keep things where they should be, as sometimes they drift apart with strangers.

I cut some pieces from a scrap lamp and used the alphabet punch on them. They certainly look better with a small touch of permanent marker.

I like how they lay on the cables. All of this gives me an old time vibe feeling.

Almost done

I just finished wiring the dtmf remote for our transmitter. Looks a bit messy but it’s more than fine for a prototype. It works too.

Sunday worklog

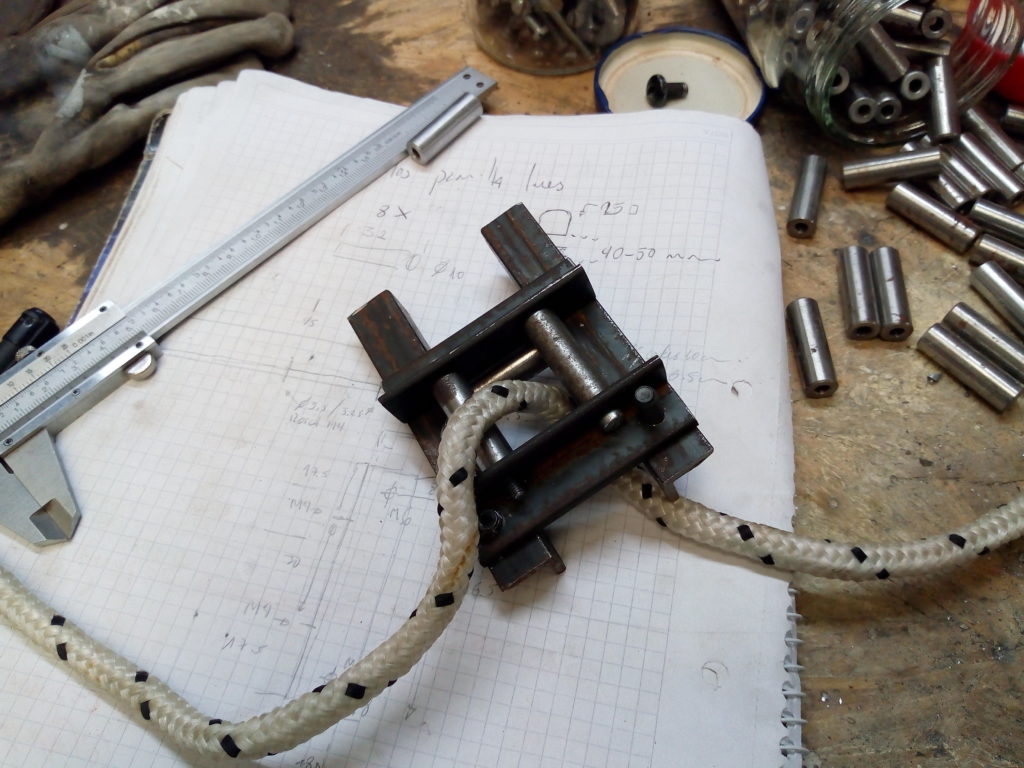

Today I started to build the rope guides for the lightning fixture. I have some nice ground rods from a textile machine that are perfect for this.

On the evening I went to Futura and cleaned up a bit the stage, moving most of it to one place:

Then I started to install real cable trays instead of our improvised version with halves of water pipes. I need to cut a small section with a special bend to accommodate the opening on the wall.

I emptied most of the rack cabinet and installed the patchbay I built earlier. I had to drill and tap another set of holes as the power outlet interfered with the movement.

I also finished that small table:

Sunday work log

Today I worked mostly on that remote control for our transmitter and on a simple pulse conditioner for a clock distribution system on our university.

We have a central clock reference used to synchronize experiments among various buildings. It’s not always spot on frequency but most of the time what matters is that its phase is continuous. There’s a network of underground cables that take that signal wherever is needed. Some of them are good despite their age (the youngest being around 10 years old) but others are crumbling and drowned.

On the seismograph building there’s a clock slaved to that signal and sometimes it looses track of it and lags as many as half an hour. Just as an experiment we decided to use the PPS signal out of a small uBlox GPS. A friend made a small module with the gps and an arduino to initialize it and display some ancillary status and I built a simple level shifter that makes a ~12V pulse out of that 3v logic output.

I also worked on the housing for the remote control. I’m using a weather proof junction box. After a bit of fumbling I had all the holes to mount the boards, connectors, indicators and cable glands done.

Then I finished a couple of details on the boards and hooked up everything for a trial run. The buttons and rf sense worked fine. But when I tried the dtmf audio input I got data on the digit outputs but nothing on the interrupt pin.

At first I thought that the module was bad (I accidentally fed it with 12V for a brief moment) and I swapped another with the same result.

I moved both of them on the breadboard and they worked fine. I inserted a bare wire on the socket and every time I touched GND with it I got an interrupt. But when installing the module that pin was stuck low. Which is quite odd.

I probed with the adjacent pins and all appeared open as they should. But there’s an unconnected pad on the other side, and there was a dead short to that. I used a scribing tool to clean up but the short persisted. That other pad, while not connected to anything on my board, was part of the dtmf module and when tied to the interrupt output it loaded it to the point of not being useful anymore.

When etching the board I used some fine steel wool and a strand perhaps stuck on the top side between the socket pins. After unseating the module, arduino and other connectors I charged a cap (around 3300uF) and applied it between the pair of shorted pins. Surely enough there was a spark.

And from then on everything worked as intended.

Lamp fixture: done

At least for now. The next step will be adding another support for the roof frame and rollers to guide the ropes around it to unblock the light path should we want to project from there.

Today I hanged the lower frame and then attached the cable trays with a set of bespoke clamps and self tapping screws.

Lamp fixture: all frames linked, attaching the cable trays

Lamp fixture: almost done

Lamp fixture: everything mounted and lifted

Lamp fixture: everything mounted and lifted

Lamp fixture, metal version.

Today I started to replace that old wooden fixture with another one made of steel.

Our original plan was to install some cable trays to have a more industrial look.

Yesterday I assembled the frames on the floor:

Today I spent most of the afternoon drilling the wood trusses on the roof and attaching the hooks. Then came the time to lower the old frame and hang the white on those hooks.

Letting it gently go down was easy:

I used some wire to attach the new frame to the old pulleys and help me lifting it near the roof. That seemed a lot easier on the planning stage but I managed to pull it off in a couple of hours.

To end this day I wound the new rope on the pulleys. Tomorrow I’ll hang the other frame (the black) and screw the trays to it.

Lamp fixture: one frame installed, another to go

Lamp fixture: one frame installed, another to go

Park bench: mount

Today I worked on the base mount for that bench. I chose a 20 degree slope (taken from that guide) as I found it comfortably and it’s a round number too.

I fumbled a bit with some pipes but the cuts and copes to build it properly are more demanding than the time I had, so I settled on some channel iron. The math is a lot easier, I just needed to offset one cut by (channel width) * tan(20°) or 2.6 cm.

I’m very pleased with how I managed to make this weld around the corner in one pass: