Today I worked mostly on that remote control for our transmitter and on a simple pulse conditioner for a clock distribution system on our university.

We have a central clock reference used to synchronize experiments among various buildings. It’s not always spot on frequency but most of the time what matters is that its phase is continuous. There’s a network of underground cables that take that signal wherever is needed. Some of them are good despite their age (the youngest being around 10 years old) but others are crumbling and drowned.

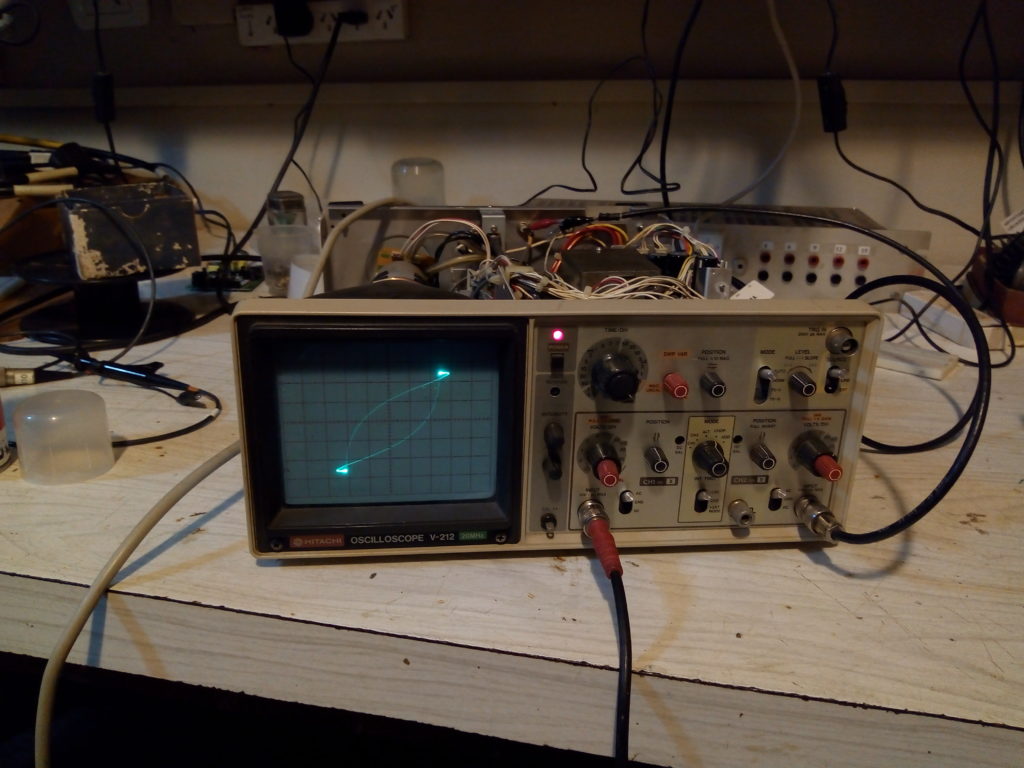

On the seismograph building there’s a clock slaved to that signal and sometimes it looses track of it and lags as many as half an hour. Just as an experiment we decided to use the PPS signal out of a small uBlox GPS. A friend made a small module with the gps and an arduino to initialize it and display some ancillary status and I built a simple level shifter that makes a ~12V pulse out of that 3v logic output.

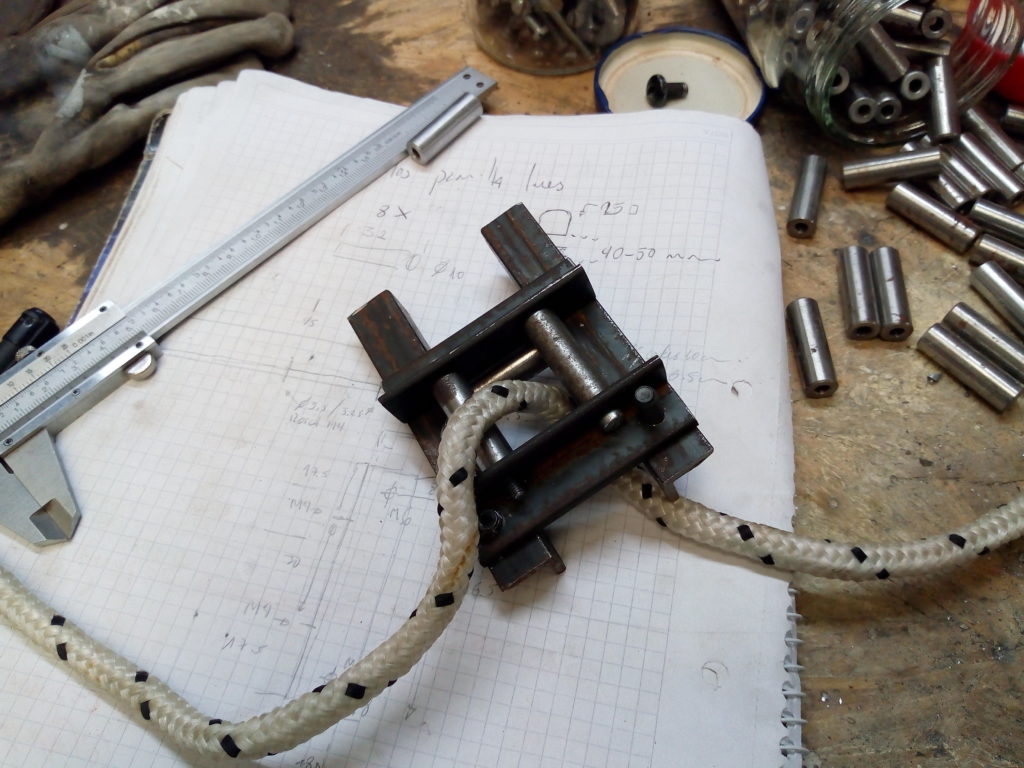

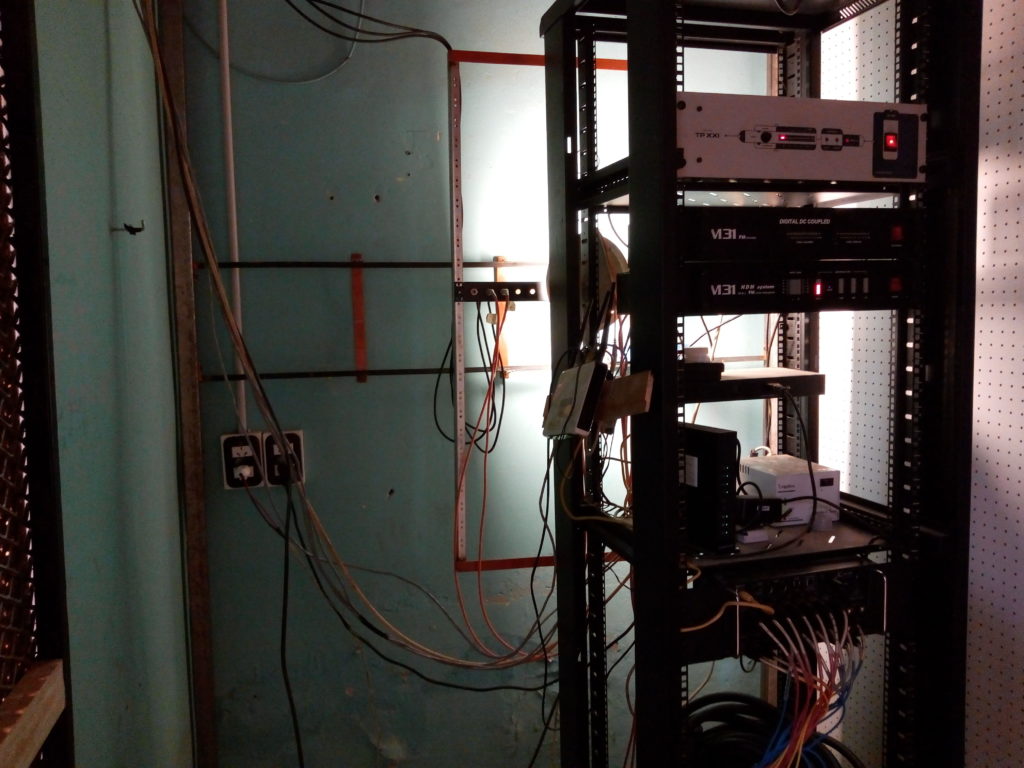

I also worked on the housing for the remote control. I’m using a weather proof junction box. After a bit of fumbling I had all the holes to mount the boards, connectors, indicators and cable glands done.

Then I finished a couple of details on the boards and hooked up everything for a trial run. The buttons and rf sense worked fine. But when I tried the dtmf audio input I got data on the digit outputs but nothing on the interrupt pin.

At first I thought that the module was bad (I accidentally fed it with 12V for a brief moment) and I swapped another with the same result.

I moved both of them on the breadboard and they worked fine. I inserted a bare wire on the socket and every time I touched GND with it I got an interrupt. But when installing the module that pin was stuck low. Which is quite odd.

I probed with the adjacent pins and all appeared open as they should. But there’s an unconnected pad on the other side, and there was a dead short to that. I used a scribing tool to clean up but the short persisted. That other pad, while not connected to anything on my board, was part of the dtmf module and when tied to the interrupt output it loaded it to the point of not being useful anymore.

When etching the board I used some fine steel wool and a strand perhaps stuck on the top side between the socket pins. After unseating the module, arduino and other connectors I charged a cap (around 3300uF) and applied it between the pair of shorted pins. Surely enough there was a spark.

And from then on everything worked as intended.