Every diamond starts as a lump of coal.

We needed a new stove for a long time and the other day I spotted this in an auction house for a fair price:

And with some care it ended up like this:

Every diamond starts as a lump of coal.

We needed a new stove for a long time and the other day I spotted this in an auction house for a fair price:

And with some care it ended up like this:

Today I bought a used battery and decided to crank this old Peugeot 504 to see if the engine was seized or other problems lurked.

It’s been sitting there since 1998 but the diesel in the tank did not smell funny so I used the little pump on the filter until it became hard. On the last strokes I heard a subtle noise and there was a tiny leak on the line.

When connecting the battery there was a small spark and the position lights turned on. I let the glow plugs do their job and tried to crank.

Nothing, just a small click of a relay inside the dash. After a couple of times it turned with some effort but refused to start.

I let the battery rest for a moment and tried again. This time it roared as I pressed the accelerator, puffed some smoke and then idled calmly. I can hardly believe it awoke from a two decade slumber just like that.

Now I have to fix the water circuit (the hoses are dry and crumbling) and the clutch so I can move it around with a bit of ease.

That shed I was cleaning needed one thing really bad, a decent floor. It was already made of concrete but with the years it broke down, revealing the soil and gravel underneath. And also wasn’t level.

So for the last couple of weeks we (my dad and I) worked together and made a new one. The next step is adding some tiles on top of that.

This happened today:

That’s a 1981 Peugeot 504 (diesel) that belonged to my grandfather. After his death about 20 years ago it’s been sitting first on the original garage and lately inside this shed that we are fixing up.

The tires have an inner tube as it was usual on that era and that’s an advantage, I doubt that any contemporary tubeless would still be sealed after spending so long being flat.

I had a bit of space to speed up while pushing and the front wheels went by with relative ease. However, there’s a small step and I couldn’t make it go further with the initial momentum alone.

I lifted the car with a jack and made a small ramp out of bricks and a slab of wood. I carefully released the jack and the car slowly moved on its own. The underside looks quite good for a machine of that vintage.

That hoist was a godsend lately. It helped me move bedroom furniture made of carob and also this old rail that weighs a ton.

During that process both of the galvanized channels I used yielded and I was this close to have everything fall down. But I won at the end.

I spent most of the last weekend studying and a bit sick.

When not reading for the Uni I binge watched a lot of talks from previous editions of the CppCon, because that’s obviously what only a sick person would do.

And after not being on that scene for quite a while I found that, like for some wines, the time made it nicer.

The use of auto variables when iterating containers, lambdas, parallelization and inclusion of atomic operations (albeit I believe they are insufficiently documented and will bite a lot of people) are just some of the things that surprised me in a good way. There’s a host of cool stuff under <algorithm> and the new optimizations (like the ones carried for constexpr ) are incredible.

Coincidentally, Bert Hubert started a series of posts with the good parts of C++ that actually makes me want to code something in it again.

A while ago we bought a very nice set of chairs with a chromed base and the bog standard pneumatic height adjustment.

After a lot of use a couple of them had the welds on the base break apart. I took one home and after thinking a bit I chose to make a stiffening plate instead of just redoing the missing parts as that area looked very flimsy.

I traced the outline on some cardboard and then cut a bit of plate with the plasma torch.

Some light prep and careful welding made it usable again. I tried first with a small 6013 rod but the arc wandered and blew a hole through the thin base. I had more success with 7018. The welds look horrible but are strong enough, I jumped a couple of times and it didn’t even notice.

Sometimes I use wire cups and wheels on the grinder. Screwing them is easy but the clearance between the guard and the tool makes it very cumbersome to use an ordinary wrench to loosen them. And also they come in different sizes.

So instead of having to carry around two tools that aren’t fit I fashioned one with some flatbar. The welds are pretty enough for a beginner and this application.

After that I gently heated it over the stove to reach a lovely shade of iridescent blue:

We are installing an intercom system and the front door unit is meant to be mounted in a recess in the wall. But the problem is that that wall is not really suitable for making such a hole.

I cut some strips of flat stock and fashioned a box. It has a couple of tabs to bolt into the wall and another ones threaded to hold the device. This is going to be painted later but I love that blue shading.

I’ve been working on and off on this for the last couple of weeks. The space we’ll have on the comms rack to handle the wiring isn’t that great and I saw on a couple of places patchbays that are articulated.

I thought on adding a twist to that and mounting everything on rails. This way I can slide it from behind the rack and then unfold it, gaining access to both sides.

We bought some pre-drilled (but not taped, ugh.) angle with the holes spaced in standard units, that was welded into a fixed frame with a couple of hinges.

This will hang from a small cart with iron wheels that rides on a couple of rails fixed to the walls.

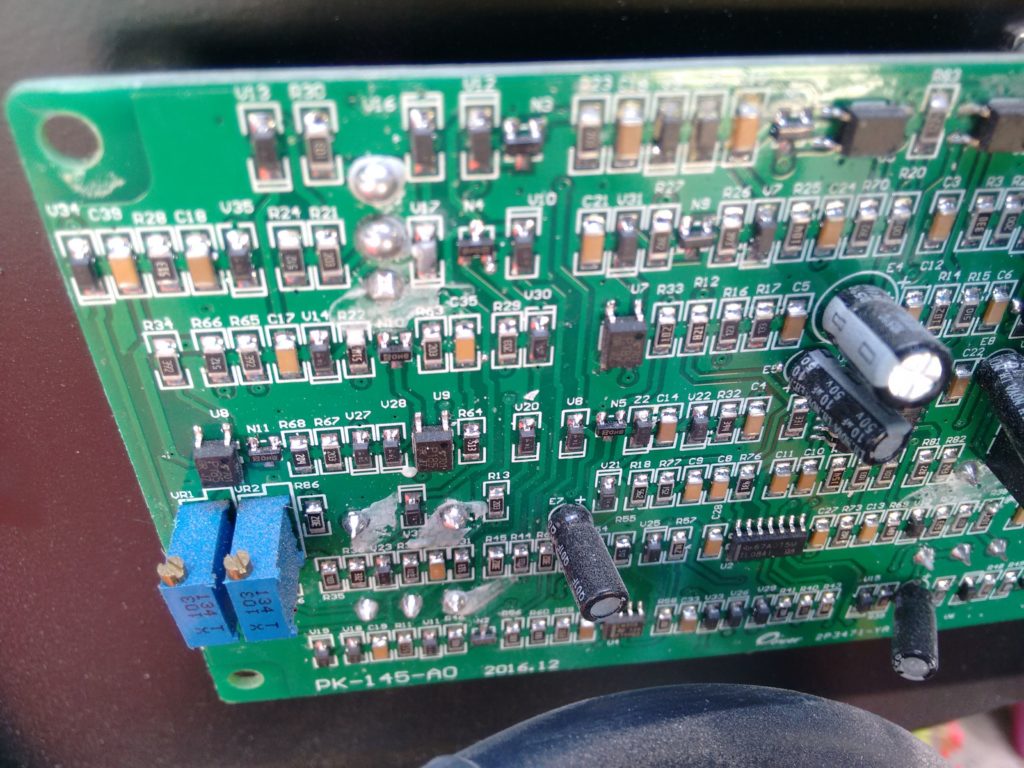

Today while working on the rack closet the welder died on me for no apparent reason. But, after power off it made a couple of noises and the fan ran for a moment.

For being a Chinese machine it actually looks quite good and neat on the inside. The boards have conformal coating and just a tad of flux residue on some pads. The only thing out of place was a blob of solder on a header instead of a jumper.

I made a couple of measurements, the high voltage section was fine but the control supply was totally dead, except for a brief moment when turning off the main switch. Traced back from that board until finding a small block with a forward converter (kinda odd, I expected a flyback). The only component with bad readings was the recovery diode. I swapped in an UF4007 and at the next flick it was alive again.

Of all the things that could go wrong with a welder on novice hands this was not expected.

The next step in the making of the rack closet is the front door frame. It’ll be screwed to the base and the top support. For that I’ll use some square tubing with a cap and nut welded to each end.

The lines scribed on those pieces look a lot like the iconic map of La Plata.

Each one was beveled and welded in the tubes. I ground the sides flat mostly for looks.

As I still had a while more with sunlight I used the support built earlier to keep them in place and tack everything together. Enough work for a Summer Friday.

So, after tearing down part of that wall we needed a safe way to store the equipment. It also has to be a bit above floor level, as we plan on making a small stage.

For the base I used some C channel iron. Parts of it were a bit mangled, so I made a makeshift tool with an hydraulic jack to spread its sides and have a good fit.

The top is simpler, it just needs to hold the vertical struts in place and the light fixture.

Then I centered it on the base and proceeded to punch and drill the holes to locate the rest of the structure:

(Sounds nicer than saying dumpster diving eh?)

We can learn a lot about a society just from looking what we throw away (see Garbology).

When I lived in Berisso it was really odd to see on the curb something that worked or was fixable.

Here in La Plata and without even trying I stumble upon stuff that is just a little bit broken if not working (albeit a tad old).

This last two months among other things I picked up with my bike basket:

This is not exactly dumpster diving but I also helped the widow of a neighbor silent key to clean up his shop.

Out of the deal I got: