Since I moved back to my childhood neighborhood I reconnected with a lot of people that were part of my developing years and imprinted many memories that I still recall fondly to this day.

One of them is a very nice old man, a bit younger than what my grandfather would be were he be still alive. From time to time I help him with the daily errands and every other week we share a simple lunch. He used to run a hardware store that marveled me every time I went (when I was a child I could be impressed with simple things. Thankfully, now I still do).

Nowadays the store is run by his sons. He comes anyways, sits on a corner drinking mate and welcomes the patrons. Besides knowing almost everyone around he’s also versed in almost any trade I can think of and that skill is quite useful, as many times people come without knowing what they need or how to fix something.

I visited him for new year’s eve and between a glass of wine he said come to the shop once the holiday craze fades, I have something for you.

A couple of days later I go to the store and without a word he carries me to the back into a room I never visited before.

This are all the returned items that we can not send for repair. Some customers are worth keeping and so we just give them a new machine instead of washing our hands because the manufacturer would not take them. Pick what you want, we’ll talk business later .

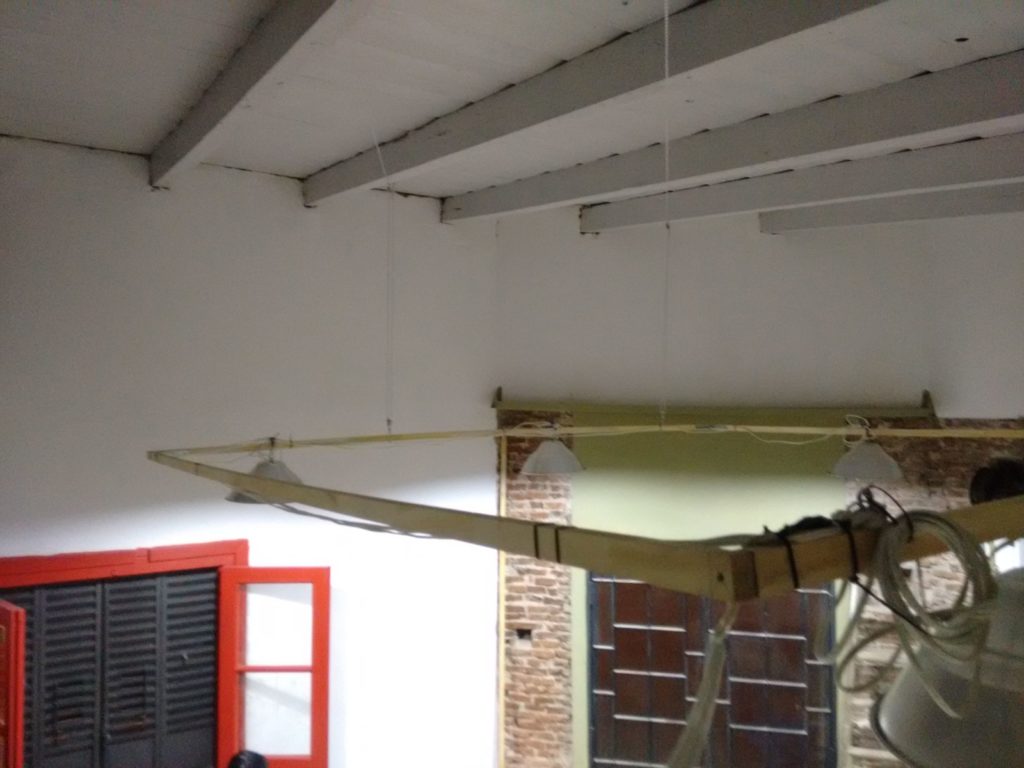

I got this out of the deal at a very discounted price:

- A combo tig/stick welder plus plasma cutting with all the standard accessories and an auto darkening mask.

- A drill press.

- A miter saw.

- Small air compressor.

Besides that he sold me safety gear, consumables and a couple of other things like magnetic squares and pressure clamps, air hoses with quick disconnects, a paint gun and a spraying one.

You don’t look at a gifted horse in the mouth but given that these were rejects I had to.

The welder was only banged a couple of times on one side and had some loose connectors. After fixing that it worked flawlessly. It came with all the torches, water tramp and pressure regulator and spares.

The compressor is way loud and one of the connections between the reservoir tanks and the regulator has a leak, I can see oil (or moisture?) bubbling when it’s running. It’s not a big deal and while the fix is easy it involves fumbling with very delicate tubing and I know from experience that a bit too much of torque can easily wreck them. Also it’s not very ergonomic, the handle has sharp edges and if I’m supposed to use it to move it around I have to crouch. As it is not very heavy I just lift it whenever I need to move.

The drill had less than the barely minimum grease on the table lift column (none) but surprisingly the chuck turned smoothly after loosening the belts. However the quill felt strange, like it was scratching something inside, and also the spring was harder than I’d like to. To dismantle it only needed a single screw to be removed and when it was out I swept the innards with a cloth and it came back with what looked like metal (or very thick paint) flakes. After making sure that none of that remained I applied a very generous amount of grease and put it back together.

Runs quite fine but the table has a bit of flex, nothing that a brace wouldn’t fix.

I don’t know what’s wrong with the miter saw. The stock abrasive disk is very soft and flexes, so making square cuts is a difficult task, and it really needs to be bolted on something hard, otherwise the frame tends to distort when applying pressure to the vise (just the necessary to keep things in place, seems like a production defect).

All of this came just in time, as I’m doing a couple of renovations on my parent’s house. (The neighbors are not exactly thrilled, as all of these tools make quite a bit of noise).